Diamond Discs

NTI diamond discs are precision instruments which are manufactured by applying the UniMatrix diamond coating technology. Thanks to this quality standard the NTI diamond discs produce an excellent surface quality and have a long service life. The discs are firmly riveted to the mandrel.

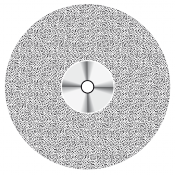

The various thicknesses of the disc blanks which range from 0.08 mm to 0.3 mm together with the grit sizes of the diamond grains (superfine, fine and medium) allow for a variety of applications. Diamond discs are used to separate crowns and bridges, to contour composite and ceramics, or to cut off ceramic press sprues. Another area of application is the fabrication of plaster models. The 365.524.450 disc in particular is ideal for separating dies. The fully diamond-coated disc 378.524.450 is well suitable for devesting pressed ceramics.

The PrimeCut SL has been developed especially for the use on all alloys, composite materials, ceramic materials and zirconia. The galvanically sintered edge offers maximum stability and a high diamond density. As a result the PrimeCut SL has a much longer service life than other discs. This improves the economical work in a dental laboratory.

In collaboration with Oliver Brix the CeraShape diamond disc with a non-cutting edge has been developed for the contouring of ceramic surfaces without creating sharp edges and nicks. The disc is used for smoothing interdental spaces and preparing surfaces in minimum time. The diamond discs 327.514.080, 361.514.080 or 363.514.100 have very small diameters and are perfect for separating crowns and bridges from zirconia blocks. The thicknesses of 0.08 mm and 0.13 mm also allow a very fine cut.

Due to their excellent service life, quality and varieties NTI diamond discs are very popular among dental technicians worldwide.