Milling Technique Cutters

Milling Technique

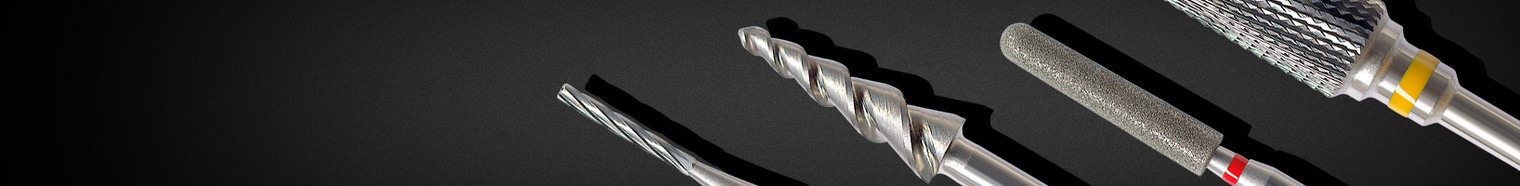

The milling technique and the processing of ceramics are among the most demanding tasks of a dental technician. NTI offers a program of the most important, current instruments for use in milling, attachment and lock technique. The instruments for the milling technique are available in 2.35 mm HP short shank (ISO 103), 3 mm HP short shank (ISO 123) as well as in 1.6 mm FG shank (ISO 316 for the milling turbine).The KR table has been developed for ceramic primary parts and milling of all alloy types. It enables the precise and reliable dressing of polishers for the milling technique as well as the milling of locking plates.

The blade configurations of the conical and parallel cutters are coordinated to the various materials, e.g. wax, NP alloys, gold or ceramics, thus enabling their efficient processing. Some instruments are available with Millennium coating. This coating prevents the usual chattering of new cutters and ensures a very long service life of the instruments.

For processing ceramic primary parts - also made of zirconia - diamond instruments (conical and parallel) with special coating for milling technique have been developed. The coating ensures good heat dissipation and thus reduces the risk of overheating the ceramic surface.

The three-step CeraGlaze ceramic polishers - known from the dental laboratory and practice - produce a smooth surface on ceramics but also on non-precious metal and titanium alloys. The GalacticGold polishers are available for all gold, precious and semi-precious alloys.

Englisch

Englisch Deutsch

Deutsch Spanisch

Spanisch Portugiesisch

Portugiesisch Italienisch

Italienisch Französisch

Französisch